Improving Efficiency with Manufacturing Software Development Services

- Manufacturing Software Development Explained

- Software Development for Manufacturing Companies at Different Scales

- Core Manufacturing Software Development Services

- Custom Manufacturing Software Solutions

- Benefits of Partnering with Reliable Manufacturing Software Development Vendors

- Manufacturing Software Development Process

- Team Setup for Manufacturing Software Development

- Choose Mobilunity as a Reliable Manufacturing Software Provider

In today’s growing industrial landscape, innovation is non-negotiable for manufacturing companies. With 71% of manufacturers planning to boost their tech spending by 10% in 2023, it’s evident that embracing technology is critical for success.

Manufacturing software development comes as a game-changer in this regard. From enterprise resource planning systems to predictive maintenance tools, these solutions help automate, streamline, and optimize various aspects of the manufacturing process.

Wondering what benefits software development for manufacturing holds? Or what are some custom manufacturing software examples? Read on to learn more about that and beyond, backed up by our expertise at Mobilunity.

Manufacturing Software Development Explained

At this point, you may wonder what manufacturing software development is. It involves creating software tailored to the unique manufacturing industry’s challenges, requirements, and tasks. Some critical aspects of such solutions are workflow automation, data processing, and operational cost optimization. Let’s discuss them in greater detail.

- Workflow automation. Efficient workflow management is crucial to ensuring smooth operations and minimizing bottlenecks. Manufacturing software development services offer automation tools that streamline various processes, like inventory management, procurement, production line, and quality control. And 45% of manufacturers consider them valuable.

- Data processing. Manufacturers generate vast amounts of data throughout their operations, from supply chain management to production activities. Owing to manufacturing software solutions, companies gather, analyze, and use this data for informed decision-making.

- Operational cost optimization. Using funds efficiently is another concern of manufacturers. They can identify inefficiencies, eliminate waste, and optimize resource allocation by implementing manufacturing software solutions.

Software Development for Manufacturing Companies at Different Scales

Software development in the manufacturing industry proves to be flexible to an extreme extent. Catering to both startups and large-grade enterprises, let’s explore how these solutions adapt to different business sizes:

- Startups. Emerging companies prioritize cost-effectiveness and scalability, which manufacturing software solutions can offer. Such businesses may leverage cloud-based platforms and various subscription models to access necessary functionalities and infrastructure without significant upfront investments.

- Small businesses. Such companies typically focus on affordability, profitability, and functionality. They can access manufacturing software for small businesses to get robust features and easy integration with their current operations.

- Mid-market enterprises. These companies have more complex manufacturing processes and higher data volumes. They require comprehensive solutions that offer end-to-end functionality across various departments.

- Large enterprises. Big corporations with extensive manufacturing operations demand highly sophisticated and integrated software. These solutions usually encompass ERP systems that seamlessly integrate manufacturing processes with other business functions such as finance, human resources, and customer relationship management.

Core Manufacturing Software Development Services

What can a manufacturing software development company offer? Here are the main services you can expect to receive:

- Strategy and consulting. These services guide businesses in developing a digital strategy, helping them leverage technology to achieve their goals and stay competitive.

- Business process management. These services focus on optimizing and streamlining manufacturing processes, improving efficiency, reducing costs, and enhancing overall operational performance.

- Order and inventory management. These services involve the development of software that automates order management and inventory tracking processes, ensuring proper inventory levels and efficient fulfillment.

- Order booking system creation. These services involve developing tools for managing and processing customer orders, providing seamless order entry, tracking, and fulfillment throughout manufacturing and delivery.

- Predictive maintenance. These services use data analysis and asset monitoring tools to predict equipment failures.

- ERP and MRP software development. These services involve building enterprise resource planning and material requirements planning software to handle manufacturing operations at each stage, including inventory management, production planning, procurement, and financials.

- Occupational and health safety management. These services involve developing software that monitors and manages occupational health and safety standards, ensuring compliance, reducing risks, and promoting a safe work environment.

- Product quality assurance. These services focus on developing software that helps monitor and maintain product quality throughout manufacturing.

- Manufacturing execution systems creation. These services involve developing systems that facilitate real-time production cycle management, from raw materials to finished products.

- BI and performance management. These services comprise building business intelligence and performance management solutions that provide manufacturers with robust data analytics and reporting tools for KPI monitoring and trend identification.

- CRM solutions development. These services focus on building customer relationship management software that helps manage customer interactions, sales channels, and marketing efforts.

- Condition monitoring solutions creation. These services comprise developing software that uses sensors and data analysis to monitor equipment health and performance.

- Equipment management software development. These services involve building software that facilitates equipment management, calibration, and maintenance.

- Employee tracking application creation. These services assist in managing employee activities, including attendance management, task assignments, and performance monitoring.

- Human-machine interface development. These services focus on creating user-friendly interfaces that enable efficient interaction between operators and manufacturing equipment.

- Legacy software modernization. These services involve upgrading outdated software systems used in manufacturing, making them compatible with modern technologies.

Custom Manufacturing Software Solutions

As you can see, numerous services involve manufacturing software application development. But what if out-of-the-box features offered by available solutions like Dynamics AX are not enough to satisfy your business needs? You can always opt for custom manufacturing software development, as many companies (61%) do.

Here are just a few examples of solutions you can build:

- Business process management tools

- ERP and MRP software

- Supply chain management systems

- Order and inventory management systems

- Occupational and health safety management solutions

- BI and performance management solutions

- Predictive maintenance tools

- Product quality assurance solutions

- CRM systems

Generally, you can create any bespoke manufacturing software solution tailored to your requirements, operations, and specifications.

Benefits of Partnering with Reliable Manufacturing Software Development Vendors

If you’ve decided to build a custom manufacturing software solution, most likely, you need a development partner. Here are several benefits you get from finding a reliable vendor:

- Expertise and industry knowledge. Software providers in manufacturing understand this sector’s unique challenges and requirements, allowing them to develop tailored solutions that address specific needs and deliver decent results.

- Customized solutions. Reliable service providers offer customized software solutions that align with your manufacturing processes and business goals. They work closely with you to understand your workflows better and identify potential issues.

- Seamless integration. Manufacturing software providers have the expertise to integrate their solutions with your existing systems, ensuring smooth implementation without disrupting ongoing operations.

- Improved efficiency. By leveraging innovative technologies and optimizing workflows, reliable vendors help manufacturers increase efficiency and productivity.

- Optimized costs. Trustworthy providers understand the importance of cost-effectiveness in the manufacturing industry and strive to deliver solutions that reduce operational costs and maximize profits. Proper budgeting for software development ensures that your project stays within financial limits without compromising quality.

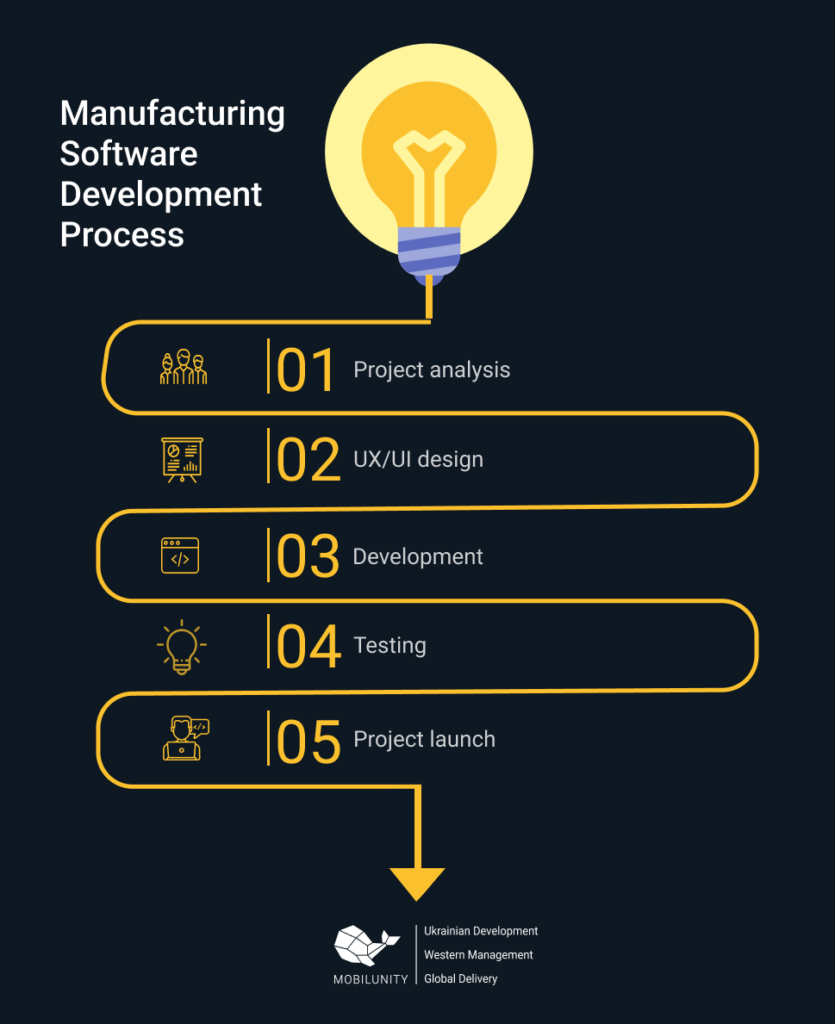

Manufacturing Software Development Process

What does it take to build a solution like Microsoft Dynamics Manufacturing? These are the core steps of software development in manufacturing:

- Project analysis. The software development team collaborates with the manufacturing company to study their requirements and goals. This stage also involves gathering information, conducting competitor research, and defining project scope, objectives, and deliverables.

- UX/UI design. Once the requirements are clear, the team designs the software’s user experience and interface. They create wireframes, prototypes, and visual elements that deliver an intuitive and user-friendly experience.

- Development. At this stage, the team transforms the design concepts into functional software. Namely, developers write code, configure databases, integrate APIs, and build the required features and functionalities.

- Testing. After the development phase, the team conducts testing to detect and fix any issues or bugs in manufacturing product development software.

- Project launch. Once the software is perfected, the project enters the launch stage. It involves deploying the solution on the manufacturing company’s infrastructure or cloud platforms. User training and documentation are also necessary at this point.

Team Setup for Manufacturing Software Development

Given the manufacturing logistics software development process described above, who handles the solution delivery? Here’s a suggested team setup that typically includes the following roles:

- Project manager — oversees the entire development process, timelines, and resources and ensures communication between the client and the development team.

- Business analyst — works closely with the client to gather and analyze requirements and translate them into software specifications.

- Software architect — designs the architecture of the software solution.

- Developers — handle the coding and software solution implementation.

- QA engineers — conduct testing to find and resolve bugs.

- UI/UX designers — create intuitive and user-friendly interfaces.

- DevOps engineers — deploy and manage the software solution and ensure smooth operations throughout the development lifecycle.

Yet, if you’re unsure about the team composition you require, you can always leverage our CTO consultancy services.

Choose Mobilunity as a Reliable Manufacturing Software Provider

Mobilunity is a trusted provider of dedicated development teams in Ukraine, offering flexible solutions for projects of any size and technology stack. We provide two models of cooperation to cater to different business needs:

- Dedicated development teams — for large-scale projects.

- Part-time consultants — for short-term projects or projects with a small workload.

Our experts specialize in creating custom web applications that address specific challenges within the manufacturing industry. Whether you require a shipping cost calculator, a time and task tracking app, or lean manufacturing in software development to streamline operations, our team can build tailored solutions that meet your unique requirements, or even hire expert logistics software developers.

Clients from countries like the UK, Germany, France, Japan, and more entrust Mobilunity with their software development needs. Our reputation extends across borders, and we have a proven track record of projects with XPLG, Zenchef, and Paidy included.

Want to transform your manufacturing operations? Contact Mobilunity for comprehensive manufacturing software development services!

Disclaimer: All salaries and prices mentioned within the article are approximate NET numbers based on the research done by our in-house Recruitment Team. Please use these numbers as a guide for comparison purposes only and feel free to use the contact form to inquire on the specific cost of the talent according to your vacancy requirements and chosen model of engagement.